Ceramic wear-lining pipes require less manpower, are easy to install and handle, and are lighter than ordinary pipes.

Ceramic Liners

- Home

- Products

- Wear Linings

- Ceramic Liners

Ceramic Lined Pipes – Ceramic Composite Wear Linings

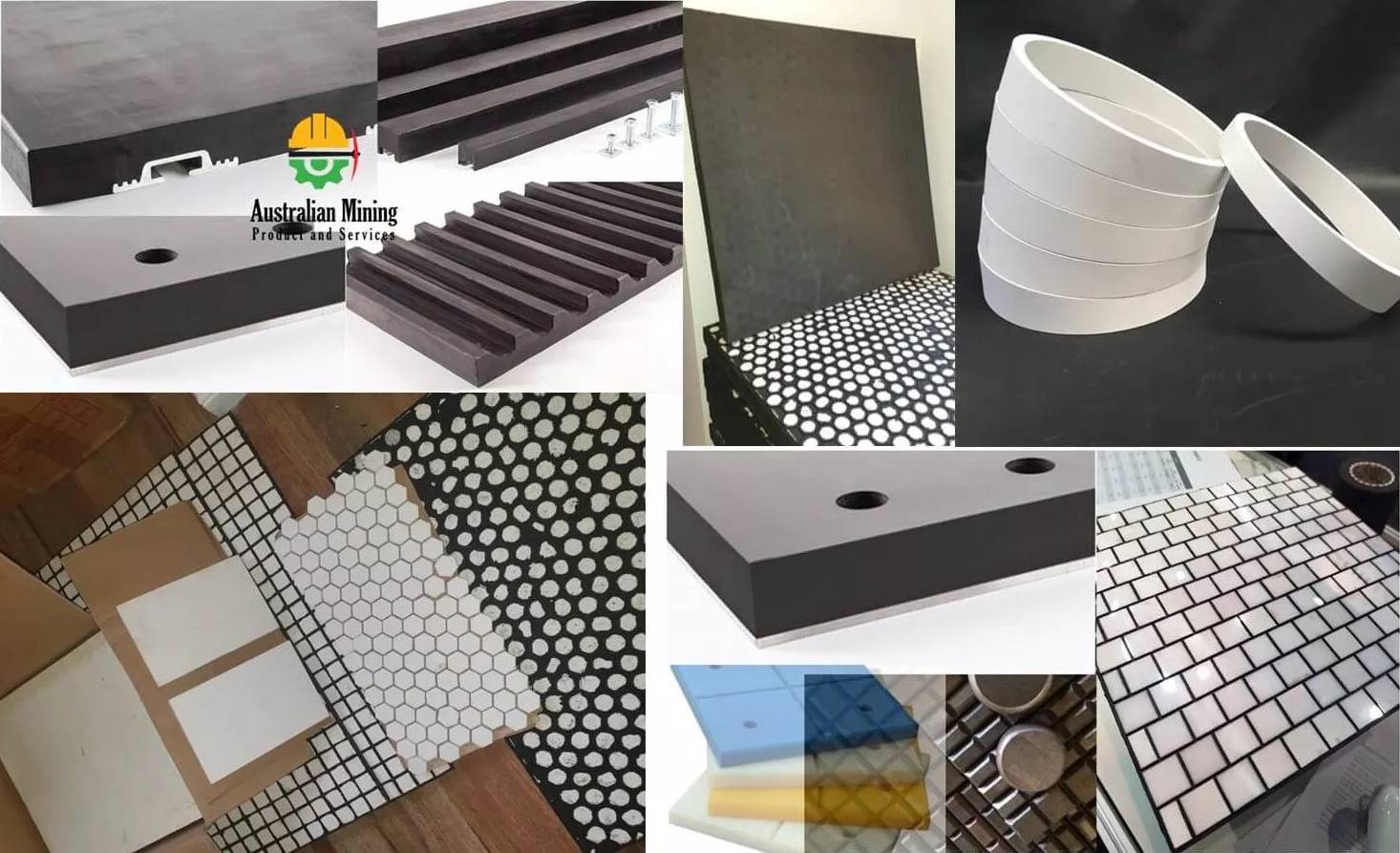

Australian Mining Products and Services offer standard and custom-designed ceramic linings to suit the operational-specific parameters of individual applications.

We have ceramic liners in a range of compounds – from

standard everyday alumina-based ceramic (Al2O3 )

ZTA ( zirconia toughened alumina )

RbSic ( Reaction bonded silicon carbides)

Silicon Nitrides

Boron Nitrides

PSZ ( Partially stabilised Zirconia)

are some of the formulations we can offer that are most often used in areas requiring reliability and longevity at a commercially acceptable price

Table of properties

| Material | Melting point °C | Density gcm -3 | Strength 1 MPa | Coefficient of thermal expansion x10 -6 /°C | Thermal conductivity W/m.k | Elastic modulus GPa |

| Al2O3 | 2050 | 4.0 | 455 | 8.0 | 40 | 380 |

| ZrO2 | 2960 | 5.6 | 175 | 7.5 | 19 | 140 |

| AlN | 1900 | 3.3 | 441 | 4.4 | 180 | 320 |

| Si3N4 | 1900 | 3.2 | 210 | 3.0 | 17 | 175 |

| B4C | 2350 | 2.5 | 350 | 4.3 | 25 | 450 |

| SiC | 2700 | 3.2 | 140 | 4.3 | 50 | 210 |

| WC | 2377 | 15.8 | 600 | 5.2 | 700 | |

| Diamond | <3000 | 3.5 | 1500 | 0.5 | 2000 | 500 |

We have stock at various locations in Western Australia, New South Wales, Victoria and Queensland

We offer from 6 mm to 112 mm thick standard Ceramic tiles on rubber backing that is either buffed or has a CN bonding layer – this specially formulated neoprene-based CN bonding layer achieves the ultimate adhesion when bonded to steel or rubber surfaces. The CN bonding layer is compatible with a wide range of Neoprene-based adhesives and allows for an excellent bonding capability even in adverse conditions and when applied with semi-skilled laborers.

We have a wide range of offerings in Reaction Bonded Silicon Carbide linings especially suitable for handling slurry in pipelines.

Our Alumina liners are usually between 92% – 95% content, depending on the applications.

All cylindrical lining can either be tiled or made up from Isostatic pressed cylinders that reduce the number of bonding

We have specially formulated PSZ ( Partially Stabilised Zirconia ) or ZTA ( Zirconia Toughened Alumina) that can be ideal for areas where there is little or no impact but require a length of extended wear life to reduce maintenance cost.

Ceramic Lined Pipes

For applications susceptible to erosive wear, ceramic-lined pipes from Australian Mining Products and Services are the best choice.

Our ceramic-lined pipes are made to outlast the linings that are frequently employed to prolong the life of piping systems, such as glass, rubber, basalt, hard-facings, and coatings.

All pipes and fittings are made of ceramic linings that are particularly wear-resistant and corrosion-resistant.

Features of Ceramic Lined Pipes

Works in High Temperature

One of the key features of ceramic-lined pipes is their ability to operate in higher temperatures for an extended period while also meeting standard working requirements.

Better Wear Resistance

Compared to regular pipes, our ceramic pipe lining can tolerate circumstances better and last longer.

Corrosion Resistance

The corrosion caused by acids and alkalies in the pipes can be prevented by ceramic wear lining pipes.

Easier Installation

Ceramic Wear Liners

In applications with sliding wear and high material speeds, Australian Mining Products and Services’ ceramic wear liner offers good wear resistance, especially when the material has a small impact angle. Our ceramic inserts are durable and the distinctive design enhances wear life and impact resistance while promoting sustainability with fewer liners. Additionally, ceramic wear liner also reduces the application’s noise and vibration.

With years of experience and industry knowledge, Australian Mining Products and Services commit to providing the best quality ceramic wear liners. As a trusted material supplier, we deliver ceramic wear liners at affordable cost, improved safety, longer service life, reduced maintenance, and maximum value. We provide supplies according to our client’s needs and requirements to help them ease their work. To know more about our ceramic wear liners or ceramic pipe lining, get in touch with us.

Benefits of Ceramic Wear Liners

Longer Wear Life

Ceramic wear lining extends the life of your machinery and boosts output in both wet and dry situations.

Flow enhancement

Boosts the process’s inefficient material flow, which is caused by confined sectors. These areas can be true bottlenecks, resulting in much extra labor and unanticipated downtime.

Lessen Noise Pollution

All ceramic wear items, like ceramic pipe linings, are quieter and improve the working environment.

Our Magnetic backed ceramic-faced wear lining – are

- Easy to install

- Require no manual handling

- Need to hot work permits

- Do not need any external scaffolding

- Are replaceable at any location to enable the plant to return to operational status with minimal downtime

If you have any more questions regarding our ceramic wear liners, call us at 1300 241 620 or email us at sales@australianminingservices.com.au.

FAQs

A ceramic protective layer covers a pipe or tube, strengthening the structure and adding extra protection against abrasions. The ceramic coating can take over to absorb wear and tear as the wall of the pipe or tube thins, owing to abrasions from the solid particulates they transmit.

In mining, mineral extraction, and power generation industries, ceramic wear solutions offer high levels of equipment protection from material abuses, extending the life of mineral processing equipment.

Yes, ceramic is wear and corrosion-resistant because it is made of minerals that can endure even in harsh environmental conditions. Apart from being wear resistance, it can also withstand high temperatures, pressure, and extreme weather conditions.

We manufacture and supply sites around Australia